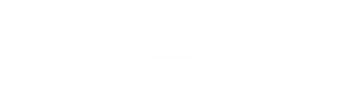

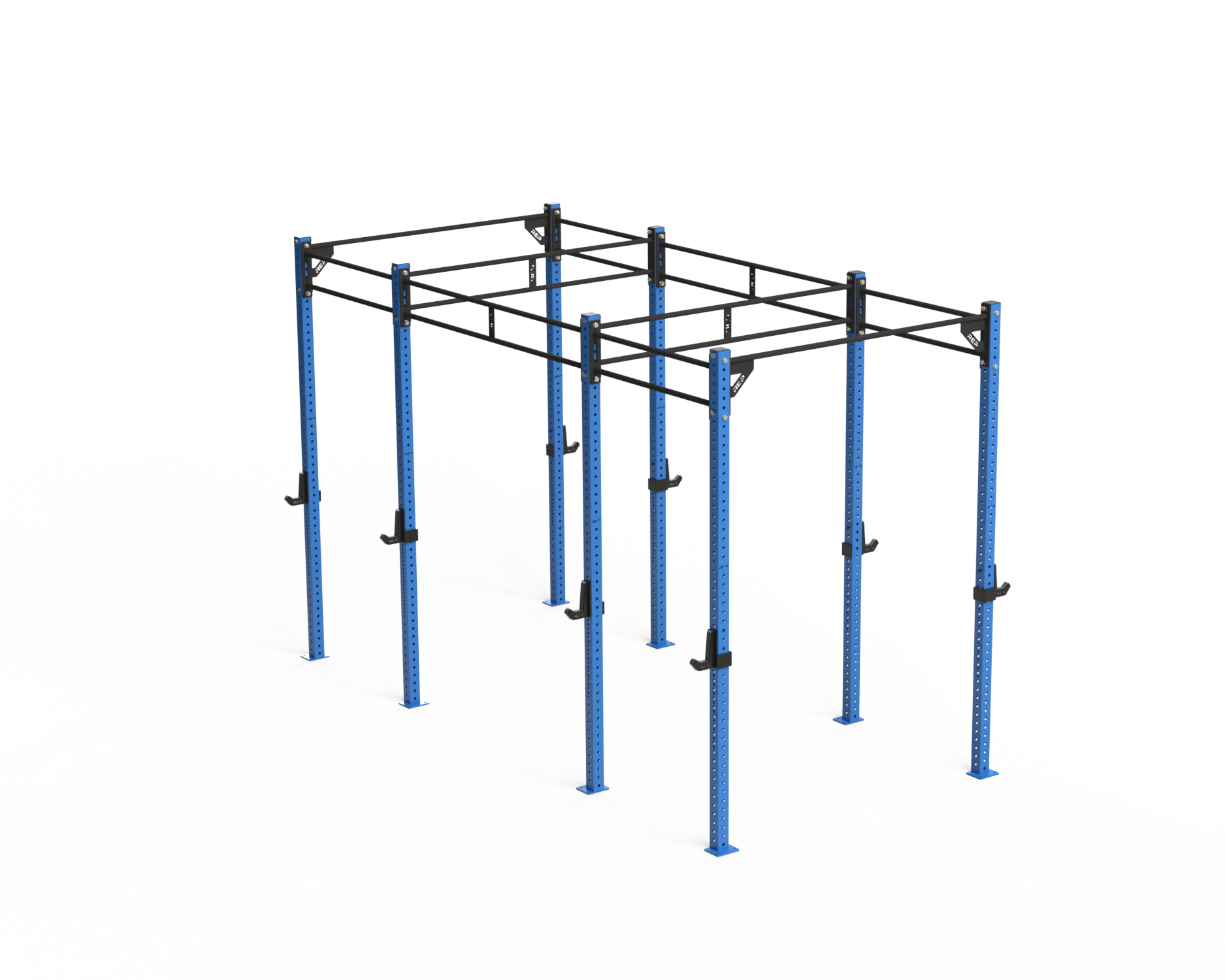

There’s a ton of power in simplicity. While our online rig builder allows you to customize the details of your gym’s commercial rig, we also offer simplified pre-selected rigs. The REP team has designed our own dream rigs of three different sizes. All options include everything you need to get started. All rigs are 9’ tall and 6’ deep. Choose the size: 14’, 20’, or 24’. The Pull-Up Connector is the traditional pull-up bar style and is used for pull-ups, muscle-ups, and more. The Double-Bar Connector offers a lower and upper traditional bar, which provides extra support and stability. Flat sandwich J-cups provide a large landing zone for the barbell. Once you choose your configuration, you can choose to further customize your rig with additional attachments, such as wall ball targets, rings, and more if you want.

REP’s rigs are tough, made with 3x3” 11-gauge steel with a 1,000lbs rackable capacity. Rigs have 1” (5000 Series) and 5/8” (4000 Series) pinhole options with 2” hole spacing on all sides (for both series), except the 4000 Series has 1” hole spacing within the bench zone. The rig also features laser-cut numbering on every hole (for the 5000 Series) and every fifth hole (for the 4000 Series), which makes it easy to arrange the attachments. REP rigs are finished with laser cutting, robotic welding, and robotic painting all under one roof to ensure a consistent, high-quality product. Your rig will be the centerpiece of your gym.

- 4000 Series

- 5000 Series

-

Material3x3" 11-gauge Steel

-

Hole Size5/8"

-

Hole Spacing1" Within Bench Zone, 2" Elsewhere

-

FinishPowder Coated

-

Depth6'

-

Width Options10', 14', 20', 24'

-

Height108"

-

Ares/Athena CompatibleNo

-

Attachment Series4000

BLOGS

Added height and various pull-up connector lengths and styles allow for more modularity - ideal for a commercial gym.

If you would like to customize your REP rig, check out our online Rig Builder. You can also add more attachments later on.

14':

8 Uprights

4 41" Double-Bar Connectors

2 Pull-Up Connectors

4 pairs of Flat Sandwich J-cups

4 72" Double-Bar Connectors

20':

10 Uprights

4 41" Double-Bar Connectors

4 Pull-Up Connectors

4 pairs of Flat Sandwich J-cups

5 72" Double-Bar Connectors

24':

12 Uprights

6 41" Double-Bar Connectors

4 Pull-Up Connectors

6 pairs of Flat Sandwich J-cups

6 72" Double-Bar Connectors

The 14' offers four barbell stations and eight bodyweight stations. The 20' offers four barbell stations and ten bodyweight stations. The 24' is spacious with plenty of working space, offering six barbell stations and twelve bodyweight stations.

The 4000 Series pinholes are 5/8". It has 1" hole spacing throughout the bench zone and 2" elsewhere for a precise liftoff height. The 5000 Series has 2" hole spacing throughout with 1" pinholes. On the 5000 Series, you can achieve 1" hole spacing on the entire rack with our Lowered J-Cups.

The 4000 Series has an impressive attachment "ecosystem", but the 5000 Series has more attachment compatibility.

The 4000 Series has laser-cut numbers every five holes making it easy to line up attachments, including J-cups. The 5000 Series has laser-cut numbers on every hole making it easy to line up attachments.

There are five key areas to consider when comparing rigs: construction, design, consistency, attachments (the “ecosystem”), and value. Here is how we compare to others on the market:

Construction: Construction refers to things like the thickness of steel, welds, and paint. We use state-of-the-art robotics in our brand-new facility to construct our rigs, including laser cutting, robotic welding, and robotic painting all under one roof. This helps ensure a consistent, high-quality product and sets the standard for precision manufacturing.

Design: Plastic liners on all attachments are standard. This is a high-end feature that helps protect the paint on your rig and keeps it looking new. Most competitors don’t offer this, or if they do, it’s inconsistently used.

We don’t use stickers. Every number and logo on the rack is laser cut or stainless steel to look great for years.In addition, we pay attention to accessory details and upgrades, including chromed weight horns (competitors use a powder coat that immediately chips and flakes away as you slide plates on/off), angled grips on our multi-grip pull-up bar, and many other fine details.

Consistency: We strive to deliver a great product to your door with no hassle. We ensure this by employing our own quality control team that is on-site daily for both inspections and training to improve production methods, such as welding (even the robots need help sometimes!) and packaging. We also ensure our packaging is designed to survive any beating it takes during delivery, so you’ll notice our boxes are reinforced and the parts within are further protected with internal packaging.

Our competitors that import often don’t spend the money for quality control, and our competitors who manufacture domestically often don’t spend the money for great packaging -- both of which lead to hassle for you as you try to get credit for damaged parts or new parts sent.

Ecosystem: A rigs attachment ecosystem is one of the biggest reasons to choose one over another. Other companies that import typically do not have a dedicated engineering team to develop new products; they simply copy what already exists. If it’s patented, they can’t copy. For domestic manufacturers, they rely on high accessory prices to make up for a lower margin on the initial rig purchase, which means any new attachments cost an arm and a leg, while our global manufacturing advantage keeps costs lower.

Value: Value is subjective, but we’re at the sweet intersection of price and quality. Spend more, and it’s likely just for a name or very minor, nonfunctional details. Spend less and you’re likely rolling the dice or giving up future attachment development. Our attachments are also developed with value in mind, and that’s an area many people ignore, to their later regret. It’s not just the base cost of the rig to consider; it’s the full attachment ecosystem and what you expect future attachments to cost.

The benefit of our scale is that we can employ the most modern manufacturing methods, including laser cutting, robotic welding, and robotic painting, resulting in a consistent, high-quality product.

Many attachments are available now and more are in development. The REP rigs are compatible with the rack attachments, making the ecosystem even larger. A rig's attachment ecosystem is one of the biggest reasons why you would choose one versus another. When you purchase a rig, you're buying into the company's ability to come out with new attachments that add additional functionality over the life of your rig. Our engineering team is hard at work developing new attachments every year, and we believe this is one of our biggest differentiators.

No, these uprights are not compatible with the Ares, Athena, or Lat Pulldown & Low Row attachments.

You can add a connector/pull-up bar to your rig upright and connect it to the Lat Pulldown & Low Row attachment setup. You would need to purchase a pair of rack uprights (80" or 93"), a Logo Plate Crossmember, and a Rear Base Stabilizer in addition to the the Lat Pulldown & Low Row (80" or 93") attachment. Our engineering team is hard at work developing new attachments every year.

Check out our rig attachment collection to learn what attachments are compatible with your rig.